LNG Point Supply– the Main Method for Gasification of Villag

发布日期:2017/06/06 来源:中国气协 本站有

人浏览

分享到:

1 Introduction

Beijing-Tianjin-Hebei is the worst air pollution region in China, and there are 8 cities in Beijing-Tianjin-Hebeilisted in the top 10 most serious atmospheric pollution cities issued by Ministry of Environmental Protection in 2015. Moreover, many cities in Beijing-Tianjin-Hebei have been covered with severe hazes in recent years. In accordance with the related investigation carried out by the Ministry of Environmental Protection, combustion of scattered coal in northern cold areas such as Beijing, Tianjin and Hebei during the heating period intensifies the haze pollution. 56,240,000 tons of scattered coal were used in villages in Beijing-Tianjin-Hebei in 2013, which include above 90% of inferior scattered coal, and the SO2, NOx and smoke dust emissions due to combustion of scattered coal are 258,900 tons, 75,700 tons and 194,300 tons, respectively, and such case indicates large application of scattered coal, poor coal quality and weak pollution control measures shall be some important causes for serious atmospheric pollution in Beijing-Tianjin-Hebei. For improving this situation, application of poor quality scattered coal must be strictly controlled from sources, and great efforts shall be taken to promote the development and utilization of clean energy in rural areas.

2 Selection of the Gasification Method

There are different methods for gasification of villages, and what described in the Rules for the Implementation of the Air Pollution Control Action Plan in Beijing-Tianjin-Hebei and Surrounding Areas are reduction of rural cooking and heating coal and increasing the cooking and heating applications of cylinder LNG and renewable energy, and rural cooking and heating by means of energy sources such as LPG, methane and natural gas rather than scattered coal. By taking those disadvantages, such as the small volume of a LPG cylinder and frequent replacing cylinders for the heating application, high costs for replacing cylinders due to villages being far away from cities, unstable supply of methane due to its unstable production, into account, natural gas becomes the ideal alternative energy source for gasification of villages. Moreover, gasification of villages is being greatly promoted and realized along with the development of LNG gasification technologies, and its advantages such as convenience, safety, being economic and high heat value.

In view of those characteristics, such as scattered rural users, being far away from the gas transmission pipeline network, and large seasonal gas consumption change, the applicable gasification methods include the method integrating the pipeline and LNG point supply modes. The pipeline gas supply method is applicable to those villages, whose distance from the medium-pressure gas pipeline is <3km, and the gasification stationgas supply method may be put into application as for those villages, whose distance from the medium-pressure gas pipeline is >3km, and each gasification station radiates its surrounding 3~5villages, and there should not be more than 2,000 households.

3 The Technical Scheme for Gasification of Villages

The technical schemes for villages primarily include the pipeline and LNG point supply methods. As for the former, gas is supplied to users through the pressure regulating stations, which is a very mature gas supply scheme. As for the latter, gas is supplied to users after regulating the pressure and odorization for LNG, and such gas supply scheme is being promoted and applied based on its advantages such as flexibility, economy, short construction period and wide coverage range. Any project for gasification of villages by means of LNG gasification stations primarily include gasification stations, gas pipelines from the gasification stations to villages and gas pipeline in villages.

3.1 LNG gasification stations

The gas station in project for gasification is small gasification. In accordance with the related requirements of Clause 9.5.1 of Code for Design of City Gas Engineering (GB50028-2006), LNG gasification station shall be equipped with a fire water supply system. The amount of fire water supply for a LNG tank shall be calculated as the total of water volumes for its fixed spray device and water gun. Moreover, in accordance with requirements of the Code for Design and Construction of Filling Station (GB50156-2012, 2014 Edition), while the volume of a LNG filling station and its LNG tanks is no more than 60m3, no fire water supply system shall be equipped.

In accordance with LNG characteristics, and in view of LNG gasification station including small volume tank, we invited experts from the chief editorial institute of Code for Design of City Gas Engineering (GB50028-2006) and related government departments to form design suggestions on some certain village gasification station.

1) The fire separation distance of the LNG gasification station shall conform to the requirements of Code for Design of City Gas Engineering (GB50028-2006).

2) While the storage scale of a LNG gasification station is no more than 50m3 and the volume of a tank is no more than 20m3, the fire water supply system may refer to requirements of LNG 3-stage stations of the Code for Design and Construction of Filling Station (GB50156-2012, 2014 Edition).

3) While the fire water supply system of the LNG gasification station is required to conform to requirements of LNG 3-stage stations of the Code for Design and Construction of Filling Station (GB50156-2012, 2014 Edition), the safety distance between the LNG gasification station and residents shall be more than 150m or calculated in accordance with the vapor cloud diffusion mode to ensure that residents shall be out of the diffusion radius.

4) While the fire water supply system of the LNG gasification station is required to conform to requirements of LNG 3-stage stations of the Code for Design and Construction of Filling Station (GB50156-2012, 2014 Edition), the heights of the tank coffer dam and the gasification station enclosure shall rise properly. While the storage scale of a LNG gasification station is no more than 50m3 and the volume of a tank is no more than 20m3, requirements of Clause 10.2.2 of the Code for Design and Construction of Filling Station (GB50156-2012, 2014 Edition) shall be implemented.

5) In accordance with LNG characteristics, while the fire water supply system of the LNG gasification station is required to conform to requirements of LNG 3-stage stations of the Code for Design and Construction of Filling Station (GB50156-2012, 2014 Edition), it is suggested that the dry powder fire extinguishers and fire blankets shall be properly increased according to the requirements of the Code for Design of Extinguisher Distribution in Buildings (GB50140-2005), and a low temperature detection system shall be equipped in accordance with requirements of Code for Design of City Gas Engineering (GB50028-2006).

The above design suggestions were formed in view of discussion of a specific project, which shall not be applicable to all rural gasification projects. Prior to issuing the technical specification for small LNG supply projects,design of any LNG gasification station shall still conform to requirements of Code for Design of City Gas Engineering (GB50028-2006).

3.2 Gas pipelines from gasification stations to villages

Gas pipelines from gasification stations to villages may be underground PE pipelines.

3.3 Gas pipelines in villages

The roads are narrow in villages, and the underground pipelines are complex without any unified plan. Gas pipelines in villages are generally the overhead type along walls, and the meterial of gas pipeline is seamless steel pipes, welded steel pipes or galvanized steel pipes. The rural gas supply pressure is 0.2~0.4MPa and gas supply pressure for residents is 2~3kPa.

The gas pressure may be regulated by means of the following four methods:

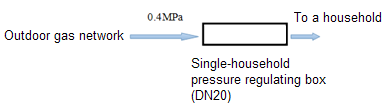

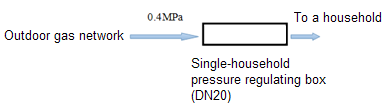

3.3.1 Single-household pressure regulating with design pressure of 0.4MPa, pressure regulating valves of DN20

The medium-pressure Grade A with pressure of 0.4MPa gas is supplied to a village, and then regulated from 0.4M to 2.5kPa through the pressure regulating valve in each household, and the minimum port of pressure regulating valves for such method is DN20. Seamless steel pipes and welding connections are recommended.

Figure 1 Single-household pressure regulating (0.4MPa)

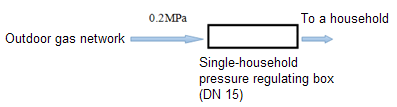

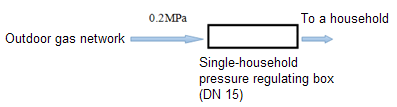

3.3.2 Single-household pressure regulating with design pressure of 0.2MPa and pressure regulating valves of DN15

The medium-pressure Grade B with pressure of 0.2MPa gas is supplied to a village, and then regulated from 0.2MPa to 2.5kPa through the pressure regulating valve in each household, and the minimum port of pressure regulating valves for such method is DN15. Seamless or galvanized steel pipes and welding connections are recommended.

Figure 2 Single-household pressure regulating (0.2MPa)

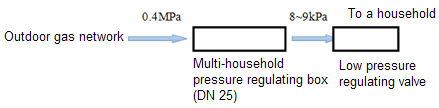

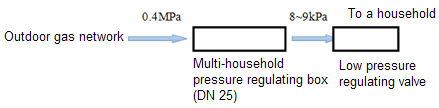

3.3.3 Multi-household pressure regulating with inlet pressure of 0.4MPa, and outlet pressure of 8~9kPa

The medium-pressure Grade A with pressure of 0.4MPa gas is supplied to a village and a pressure regulating box is equipped in an appropriate location for regulating the gas pressure from 0.4MPa to 8~9kPa to the low pressure users, and then there is a low pressure regulating valve for regulating the gas pressure to 2.5kPa for resident application in the gasmeter box for each user. Seamless steel pipes and welding connections are recommended for medium-pressure Grade A gas pipelines, and seamless or galvanized steel pipes and welding connections are recommended for low pressure gas pipelines.

Figure 3 Multi-household pressure regulating (8~9kPa)

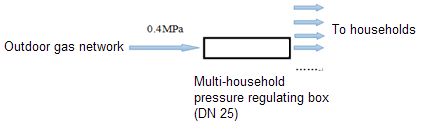

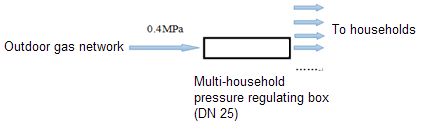

3.3.4 Multi-household pressure regulating with inlet pressure 0.4MPa, and outlet pressure of 3kPa

The medium-pressure Grade A with pressure of 0.4MPa gas is supplied to a village and a pressure regulating box is equipped in an appropriate location for regulating the gas pressure from 0.4MPa to 3kPa to the low pressure users. Seamless steel pipes and welding connections are recommended for medium-pressure Grade A gas pipelines, and seamless or galvanized steel pipes and welding or threaded connections are recommended for low pressure gas pipelines.

Figure 4 Multi-household pressure regulating (3kPa)

3.3.5 Comparison of pressure regulating methods

By taking a village of 200 households as an example, the pipeline pavement method is the overhead type along walls and seamless steel pipes are use, and a single household project construction costs of the outdoor overhead gas pipelines excluding the gasification station, PE pipelines outside the village and gas pipeline inside the household for the various pressure regulating methods are shown in Table 1.

Table 1 A single household project construction costs of the outdoor overhead gas pipelinesfor the various pressure regulating methods

The above project construction costs are only applicable to comparison and selection under certain conditions, and primarily for economical comparison and selection of the pressure regulating method. The specific project construction costs may correspondingly change along with changing prices of valves and materials, the distribution of the village, the village topography and construction difficulty and other factors.

4 Conclusions

In accordance with the design experiences of a rural gasification project, the following conclusions are obtained:

1) The rural gas consumption is relatively small and the gas price bearing ability is low, and the project investment shall be lowered as can as possible on the premise of guaranteeing safety to reduce the burden of the companies and rural residents, thus, a fire control system may not be equipped as can as possible after receiving the construction approval of a gasification station from the relevant departments.

2) The single-household project costs fall along with the growth of the number of households in a village. In view of economy and safety, the multi-household pressure regulating method is recommended with the inlet pressure of 0.4MPa, and the outlet pressure of 8~9kPa.

Beijing-Tianjin-Hebei is the worst air pollution region in China, and there are 8 cities in Beijing-Tianjin-Hebeilisted in the top 10 most serious atmospheric pollution cities issued by Ministry of Environmental Protection in 2015. Moreover, many cities in Beijing-Tianjin-Hebei have been covered with severe hazes in recent years. In accordance with the related investigation carried out by the Ministry of Environmental Protection, combustion of scattered coal in northern cold areas such as Beijing, Tianjin and Hebei during the heating period intensifies the haze pollution. 56,240,000 tons of scattered coal were used in villages in Beijing-Tianjin-Hebei in 2013, which include above 90% of inferior scattered coal, and the SO2, NOx and smoke dust emissions due to combustion of scattered coal are 258,900 tons, 75,700 tons and 194,300 tons, respectively, and such case indicates large application of scattered coal, poor coal quality and weak pollution control measures shall be some important causes for serious atmospheric pollution in Beijing-Tianjin-Hebei. For improving this situation, application of poor quality scattered coal must be strictly controlled from sources, and great efforts shall be taken to promote the development and utilization of clean energy in rural areas.

2 Selection of the Gasification Method

There are different methods for gasification of villages, and what described in the Rules for the Implementation of the Air Pollution Control Action Plan in Beijing-Tianjin-Hebei and Surrounding Areas are reduction of rural cooking and heating coal and increasing the cooking and heating applications of cylinder LNG and renewable energy, and rural cooking and heating by means of energy sources such as LPG, methane and natural gas rather than scattered coal. By taking those disadvantages, such as the small volume of a LPG cylinder and frequent replacing cylinders for the heating application, high costs for replacing cylinders due to villages being far away from cities, unstable supply of methane due to its unstable production, into account, natural gas becomes the ideal alternative energy source for gasification of villages. Moreover, gasification of villages is being greatly promoted and realized along with the development of LNG gasification technologies, and its advantages such as convenience, safety, being economic and high heat value.

In view of those characteristics, such as scattered rural users, being far away from the gas transmission pipeline network, and large seasonal gas consumption change, the applicable gasification methods include the method integrating the pipeline and LNG point supply modes. The pipeline gas supply method is applicable to those villages, whose distance from the medium-pressure gas pipeline is <3km, and the gasification stationgas supply method may be put into application as for those villages, whose distance from the medium-pressure gas pipeline is >3km, and each gasification station radiates its surrounding 3~5villages, and there should not be more than 2,000 households.

3 The Technical Scheme for Gasification of Villages

The technical schemes for villages primarily include the pipeline and LNG point supply methods. As for the former, gas is supplied to users through the pressure regulating stations, which is a very mature gas supply scheme. As for the latter, gas is supplied to users after regulating the pressure and odorization for LNG, and such gas supply scheme is being promoted and applied based on its advantages such as flexibility, economy, short construction period and wide coverage range. Any project for gasification of villages by means of LNG gasification stations primarily include gasification stations, gas pipelines from the gasification stations to villages and gas pipeline in villages.

3.1 LNG gasification stations

The gas station in project for gasification is small gasification. In accordance with the related requirements of Clause 9.5.1 of Code for Design of City Gas Engineering (GB50028-2006), LNG gasification station shall be equipped with a fire water supply system. The amount of fire water supply for a LNG tank shall be calculated as the total of water volumes for its fixed spray device and water gun. Moreover, in accordance with requirements of the Code for Design and Construction of Filling Station (GB50156-2012, 2014 Edition), while the volume of a LNG filling station and its LNG tanks is no more than 60m3, no fire water supply system shall be equipped.

In accordance with LNG characteristics, and in view of LNG gasification station including small volume tank, we invited experts from the chief editorial institute of Code for Design of City Gas Engineering (GB50028-2006) and related government departments to form design suggestions on some certain village gasification station.

1) The fire separation distance of the LNG gasification station shall conform to the requirements of Code for Design of City Gas Engineering (GB50028-2006).

2) While the storage scale of a LNG gasification station is no more than 50m3 and the volume of a tank is no more than 20m3, the fire water supply system may refer to requirements of LNG 3-stage stations of the Code for Design and Construction of Filling Station (GB50156-2012, 2014 Edition).

3) While the fire water supply system of the LNG gasification station is required to conform to requirements of LNG 3-stage stations of the Code for Design and Construction of Filling Station (GB50156-2012, 2014 Edition), the safety distance between the LNG gasification station and residents shall be more than 150m or calculated in accordance with the vapor cloud diffusion mode to ensure that residents shall be out of the diffusion radius.

4) While the fire water supply system of the LNG gasification station is required to conform to requirements of LNG 3-stage stations of the Code for Design and Construction of Filling Station (GB50156-2012, 2014 Edition), the heights of the tank coffer dam and the gasification station enclosure shall rise properly. While the storage scale of a LNG gasification station is no more than 50m3 and the volume of a tank is no more than 20m3, requirements of Clause 10.2.2 of the Code for Design and Construction of Filling Station (GB50156-2012, 2014 Edition) shall be implemented.

5) In accordance with LNG characteristics, while the fire water supply system of the LNG gasification station is required to conform to requirements of LNG 3-stage stations of the Code for Design and Construction of Filling Station (GB50156-2012, 2014 Edition), it is suggested that the dry powder fire extinguishers and fire blankets shall be properly increased according to the requirements of the Code for Design of Extinguisher Distribution in Buildings (GB50140-2005), and a low temperature detection system shall be equipped in accordance with requirements of Code for Design of City Gas Engineering (GB50028-2006).

The above design suggestions were formed in view of discussion of a specific project, which shall not be applicable to all rural gasification projects. Prior to issuing the technical specification for small LNG supply projects,design of any LNG gasification station shall still conform to requirements of Code for Design of City Gas Engineering (GB50028-2006).

3.2 Gas pipelines from gasification stations to villages

Gas pipelines from gasification stations to villages may be underground PE pipelines.

3.3 Gas pipelines in villages

The roads are narrow in villages, and the underground pipelines are complex without any unified plan. Gas pipelines in villages are generally the overhead type along walls, and the meterial of gas pipeline is seamless steel pipes, welded steel pipes or galvanized steel pipes. The rural gas supply pressure is 0.2~0.4MPa and gas supply pressure for residents is 2~3kPa.

The gas pressure may be regulated by means of the following four methods:

3.3.1 Single-household pressure regulating with design pressure of 0.4MPa, pressure regulating valves of DN20

The medium-pressure Grade A with pressure of 0.4MPa gas is supplied to a village, and then regulated from 0.4M to 2.5kPa through the pressure regulating valve in each household, and the minimum port of pressure regulating valves for such method is DN20. Seamless steel pipes and welding connections are recommended.

Figure 1 Single-household pressure regulating (0.4MPa)

3.3.2 Single-household pressure regulating with design pressure of 0.2MPa and pressure regulating valves of DN15

The medium-pressure Grade B with pressure of 0.2MPa gas is supplied to a village, and then regulated from 0.2MPa to 2.5kPa through the pressure regulating valve in each household, and the minimum port of pressure regulating valves for such method is DN15. Seamless or galvanized steel pipes and welding connections are recommended.

Figure 2 Single-household pressure regulating (0.2MPa)

3.3.3 Multi-household pressure regulating with inlet pressure of 0.4MPa, and outlet pressure of 8~9kPa

The medium-pressure Grade A with pressure of 0.4MPa gas is supplied to a village and a pressure regulating box is equipped in an appropriate location for regulating the gas pressure from 0.4MPa to 8~9kPa to the low pressure users, and then there is a low pressure regulating valve for regulating the gas pressure to 2.5kPa for resident application in the gasmeter box for each user. Seamless steel pipes and welding connections are recommended for medium-pressure Grade A gas pipelines, and seamless or galvanized steel pipes and welding connections are recommended for low pressure gas pipelines.

Figure 3 Multi-household pressure regulating (8~9kPa)

3.3.4 Multi-household pressure regulating with inlet pressure 0.4MPa, and outlet pressure of 3kPa

The medium-pressure Grade A with pressure of 0.4MPa gas is supplied to a village and a pressure regulating box is equipped in an appropriate location for regulating the gas pressure from 0.4MPa to 3kPa to the low pressure users. Seamless steel pipes and welding connections are recommended for medium-pressure Grade A gas pipelines, and seamless or galvanized steel pipes and welding or threaded connections are recommended for low pressure gas pipelines.

Figure 4 Multi-household pressure regulating (3kPa)

3.3.5 Comparison of pressure regulating methods

By taking a village of 200 households as an example, the pipeline pavement method is the overhead type along walls and seamless steel pipes are use, and a single household project construction costs of the outdoor overhead gas pipelines excluding the gasification station, PE pipelines outside the village and gas pipeline inside the household for the various pressure regulating methods are shown in Table 1.

Table 1 A single household project construction costs of the outdoor overhead gas pipelinesfor the various pressure regulating methods

| Pressure regulating method | A single household project construction costs(Yuan/household) |

| Single-household pressure regulating (0.4MPa) | 2000 |

| Single-household pressure regulating (0.2MPa) | 2200 |

| Multi-household pressure regulating (8~9kPa) | 1650 |

| Multi-household pressure regulating (3kPa) | 1800 |

The above project construction costs are only applicable to comparison and selection under certain conditions, and primarily for economical comparison and selection of the pressure regulating method. The specific project construction costs may correspondingly change along with changing prices of valves and materials, the distribution of the village, the village topography and construction difficulty and other factors.

4 Conclusions

In accordance with the design experiences of a rural gasification project, the following conclusions are obtained:

1) The rural gas consumption is relatively small and the gas price bearing ability is low, and the project investment shall be lowered as can as possible on the premise of guaranteeing safety to reduce the burden of the companies and rural residents, thus, a fire control system may not be equipped as can as possible after receiving the construction approval of a gasification station from the relevant departments.

2) The single-household project costs fall along with the growth of the number of households in a village. In view of economy and safety, the multi-household pressure regulating method is recommended with the inlet pressure of 0.4MPa, and the outlet pressure of 8~9kPa.

京公网安备 11010502042381号

京公网安备 11010502042381号