Disccusion on Beijing Rural “Coal-to-Gas” Gas Supply

发布日期:2017/06/06 来源:中国气协 本站有

人浏览

分享到:

1 Background

North China has been frequently affected by haze since 2013, the air pollution is serious and the PM2.5 concentration always breaks the record. Although Clean Air Actions has been taken for years, taking measures of coal-to-gas, coal-to-electricity to reduce the total coal consumption amount, the haze pollution situationis still severe and the prevention and control tasks are still arduous. In accordance with tested results from a research institute, the current PM2.5 emissions intensity of small rural coal-fired stoves coal is up to 3.7g/kg coal, whose unit fuel combustion PM2.5 emissions is 4~10 times of that of a large coal-fired boiler coal, Moreover, the PM2.5 and SO2 emmissions of small coal-fired stoves is 6 times and 2.5 times of the total annual emissions of the original four coal-fired power plants in Beijing, respectively. Beijing rural scattered coal combustion PM2.5 emissions contribute 14.4~18.5% of pollution emissions in Beijing.

Beijing rural Clean Air Action by Means of Reduction or Replacement of Coal is an important measure for Beijing Municipal Committee of the CPC and People's Government of Beijing Municipality to implement air pollution in the capital required by the Party Central Committee and State Council. It is clearly put forward in the document of Division of Key Tasks Beijing 2013-2017 Clean Air Action Plan (Beijing Government Office Document No.:[2013] 49), issued by the People's Government of Beijing Municipality, that reduction or replacement of coal and heating by means of clean energy are main tasks of the Clean Air Action Plan during the 13th Five-Year Plan for rural-urban fringe zones and villages.

At present, the rural clean energy transformation methods primarily include “coal-to-gas”and “coal-to-electricity”. By combining heating characteristics of Beijing farmhouses, the characteristics and applicability of the rural “coal-to-gas” supply method was discussed in this study.

2 Investigation of the Current Situations of Beijing Villages

In accordance with data from Beijing Rural Work Committee in June 2013, there are 3590 suburb administrative villages in Beijing, and they are distributed in Fangshan, Tongzhou, Shunyi, Changping, Daxing, Mentougou, Huairou, Pinggu, Miyun and Yanqing.

In accordance with the New Countryside Plan, the current 3,590 villages will have been integrated into 1,906 administrative villages in Beijing suburbs by 2020, and the total number of households will be 580,000. According to statistics, the number of households in a village is primarily below 600, and those villages below 300 households per village accounts for 61% of the total villages. In accordance with the geographical location of each village, the preliminary judgment is that about 1,409 villages and 497 villages are located in the plain and mountains areas, respectively. By taking the spacing distances between villages and natural gas pipelines, farmhouse heating conditions and implementation conditions, the applicability of the specific rural “coal-to-gas” method was judged in view of the economic rationality.

3 Current Heating Situations of Beijing Farmhouses

3.1 Weak thermal insulation properties of the general farmhouses

90% of Beijing rural residential buildings are seated in north but facing the south, and the most of the farmhouses are courtyard type single-store slope roof residential buildings, with 100-120m2 building area per household. Farmhouse building envelopes primarily include clay bricks and windows are mainly single-layer glass with wood frame. With support of the new countryside construction fiscal subsidies from the government, heat preservation treatment has been performed to building structures offarmhousein recent years. Polystyrene board insulation was taken on external walls of about 1/3 of residential buildings, but no heat preservation measure was taken to the other 2/3 of farmhouses. Overall, thermal insulation properties of Beijing farmhouses are weak so that the building heating energy consumption is relatively high.

3.2 Coal dominats the heating methods

In accordance with the related survey, the ratios of various energy sources for energy consumption of Beijing farmhouses are as follows: coal: 74%, electricity: 13%, LPG: 8%, straw: 4.5%, and solar energy and other renewable energy: 0.5%. The heating energy consumption accounts for about 60% of the rural energy consumption.

3.3 The comfortable temperature requirement for the farmhouses in the heating period is lower than the standard for towns

In accordance with the thermal comfort study of Tsinghua University on Beijing farmhouses during the heating period, the moderate temperature for farmhouses is 18.4°C and the lower acceptable temperature is 10.9°C; and the comfortable temperature is primarily based on the dressing habits and way of life of farmers. Thus, the heating temperature for Beijing farmhouses shall not obey to the heating standard for urban flat residential buildings, and the indoor temperature shall not be very different from the outdoor.

4 Analysis of Heating Characteristics of a Typical Farmhouse

Investigation results show that most of the farmhouses are courtyard type single-store slope roof residential buildings with 100~120m2 building area per household, on the other hand, heating is primarily limited to the living room and two bedrooms per household. The shading effect is only considered as for wing-rooms, and generally without heating. The building materials are mainly clay bricks or stones, doors are primarily wood doors, and windows are mostly the single-layer glass with wood frame.

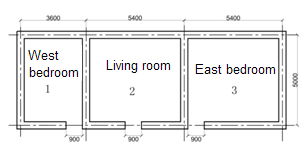

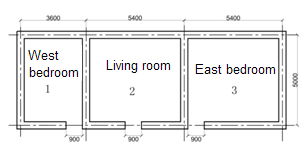

For analysis of heating characteristics of farmhouses, the typical farmhouse model have the specific parameters as follows, heating is only for the living room and two bedrooms, with 72m2 heating area, being seated in north but facing the south, 37mm common clay bricks walls, single-layer wood doors, single-layer glass with wood frame windows, timber work slope roof, and window-wall ratio is 0.679, shape coefficient of building is 0.896.

Figure 1 A typical rural residential building plan (unit: mm)

For understanding the heating characteristics of the typical farmhouse, the energy saving transformation and heat consumption analysis were carried out based on the above model. The outdoor temperature is taken as -9°C and the indoor temperature is 16°C with the calculated heating outdoor temperature in Beijing, and heat transfer coefficients of the building materials are shown in Table 1. The calculated heat consumptions and the total unit building area heat consumption are presented in Table 2.

Table 1 Heat transfer coefficientsof building materials

North China has been frequently affected by haze since 2013, the air pollution is serious and the PM2.5 concentration always breaks the record. Although Clean Air Actions has been taken for years, taking measures of coal-to-gas, coal-to-electricity to reduce the total coal consumption amount, the haze pollution situationis still severe and the prevention and control tasks are still arduous. In accordance with tested results from a research institute, the current PM2.5 emissions intensity of small rural coal-fired stoves coal is up to 3.7g/kg coal, whose unit fuel combustion PM2.5 emissions is 4~10 times of that of a large coal-fired boiler coal, Moreover, the PM2.5 and SO2 emmissions of small coal-fired stoves is 6 times and 2.5 times of the total annual emissions of the original four coal-fired power plants in Beijing, respectively. Beijing rural scattered coal combustion PM2.5 emissions contribute 14.4~18.5% of pollution emissions in Beijing.

Beijing rural Clean Air Action by Means of Reduction or Replacement of Coal is an important measure for Beijing Municipal Committee of the CPC and People's Government of Beijing Municipality to implement air pollution in the capital required by the Party Central Committee and State Council. It is clearly put forward in the document of Division of Key Tasks Beijing 2013-2017 Clean Air Action Plan (Beijing Government Office Document No.:[2013] 49), issued by the People's Government of Beijing Municipality, that reduction or replacement of coal and heating by means of clean energy are main tasks of the Clean Air Action Plan during the 13th Five-Year Plan for rural-urban fringe zones and villages.

At present, the rural clean energy transformation methods primarily include “coal-to-gas”and “coal-to-electricity”. By combining heating characteristics of Beijing farmhouses, the characteristics and applicability of the rural “coal-to-gas” supply method was discussed in this study.

2 Investigation of the Current Situations of Beijing Villages

In accordance with data from Beijing Rural Work Committee in June 2013, there are 3590 suburb administrative villages in Beijing, and they are distributed in Fangshan, Tongzhou, Shunyi, Changping, Daxing, Mentougou, Huairou, Pinggu, Miyun and Yanqing.

In accordance with the New Countryside Plan, the current 3,590 villages will have been integrated into 1,906 administrative villages in Beijing suburbs by 2020, and the total number of households will be 580,000. According to statistics, the number of households in a village is primarily below 600, and those villages below 300 households per village accounts for 61% of the total villages. In accordance with the geographical location of each village, the preliminary judgment is that about 1,409 villages and 497 villages are located in the plain and mountains areas, respectively. By taking the spacing distances between villages and natural gas pipelines, farmhouse heating conditions and implementation conditions, the applicability of the specific rural “coal-to-gas” method was judged in view of the economic rationality.

3 Current Heating Situations of Beijing Farmhouses

3.1 Weak thermal insulation properties of the general farmhouses

90% of Beijing rural residential buildings are seated in north but facing the south, and the most of the farmhouses are courtyard type single-store slope roof residential buildings, with 100-120m2 building area per household. Farmhouse building envelopes primarily include clay bricks and windows are mainly single-layer glass with wood frame. With support of the new countryside construction fiscal subsidies from the government, heat preservation treatment has been performed to building structures offarmhousein recent years. Polystyrene board insulation was taken on external walls of about 1/3 of residential buildings, but no heat preservation measure was taken to the other 2/3 of farmhouses. Overall, thermal insulation properties of Beijing farmhouses are weak so that the building heating energy consumption is relatively high.

3.2 Coal dominats the heating methods

In accordance with the related survey, the ratios of various energy sources for energy consumption of Beijing farmhouses are as follows: coal: 74%, electricity: 13%, LPG: 8%, straw: 4.5%, and solar energy and other renewable energy: 0.5%. The heating energy consumption accounts for about 60% of the rural energy consumption.

3.3 The comfortable temperature requirement for the farmhouses in the heating period is lower than the standard for towns

In accordance with the thermal comfort study of Tsinghua University on Beijing farmhouses during the heating period, the moderate temperature for farmhouses is 18.4°C and the lower acceptable temperature is 10.9°C; and the comfortable temperature is primarily based on the dressing habits and way of life of farmers. Thus, the heating temperature for Beijing farmhouses shall not obey to the heating standard for urban flat residential buildings, and the indoor temperature shall not be very different from the outdoor.

4 Analysis of Heating Characteristics of a Typical Farmhouse

Investigation results show that most of the farmhouses are courtyard type single-store slope roof residential buildings with 100~120m2 building area per household, on the other hand, heating is primarily limited to the living room and two bedrooms per household. The shading effect is only considered as for wing-rooms, and generally without heating. The building materials are mainly clay bricks or stones, doors are primarily wood doors, and windows are mostly the single-layer glass with wood frame.

For analysis of heating characteristics of farmhouses, the typical farmhouse model have the specific parameters as follows, heating is only for the living room and two bedrooms, with 72m2 heating area, being seated in north but facing the south, 37mm common clay bricks walls, single-layer wood doors, single-layer glass with wood frame windows, timber work slope roof, and window-wall ratio is 0.679, shape coefficient of building is 0.896.

Figure 1 A typical rural residential building plan (unit: mm)

For understanding the heating characteristics of the typical farmhouse, the energy saving transformation and heat consumption analysis were carried out based on the above model. The outdoor temperature is taken as -9°C and the indoor temperature is 16°C with the calculated heating outdoor temperature in Beijing, and heat transfer coefficients of the building materials are shown in Table 1. The calculated heat consumptions and the total unit building area heat consumption are presented in Table 2.

Table 1 Heat transfer coefficientsof building materials

| Building material | Heat transfer coefficient /(W·m-2·K-1) |

|---|---|

| Single-layer wood door | 4.65 |

| Single-layer glass with wood frame window | 5.82 |

| 37mm clay bricks | 1.57 |

| Wood roof | 1.64 |

Table 2 Heat consumptions of various rooms and the total unit building area heat consumption

| Heat consumption (Room No. 1) /W | 2854.76 |

| Heat consumption (Room No. 2) /W | 3285.29 |

| Heat consumption (Room No. 3) /W | 3869.93 |

| Total heat consumption /W | 10009.98 |

| Unit building area heat consumption /(W·m-2) | 139.03 |

The above data indicate that the unit area heat consumption of the farmhouse is much more than that of the urban residential buildings which is 60W/m2. In addition, it can be seen through analysis of the heat consumption of the building envelope (Table 3) that the basic heat consumption of the building envelope accounts for 93.3% of the total heat consumption. The heat consumption of the floors is relatively small, but the heat consumptions for walls, the roof and doors/windows are relatively large, thus, improvement of their heat insulation performances may lead to reduction of the building heat consumption and primarily improvement of the indoor heating temperature. Currently, the rural existing buildings are not insulated, thus, thermal insulation shall first be carried out to houses as for replacement of scattered coal and clean energy transformation.

Table 3 Building envelope heat consumption

Table 3 Building envelope heat consumption

| Basic heat consumption of the building envelop /(W·m-2) | Walls | 3059.47 |

| Roof | 2396.98 | |

| Floor | 913.35 | |

| Doors and windows | 2977.33 | |

| Heat consumption due to cold air infiltration/(W·m-2) | 254.80 | |

| Heat consumption due to cold air invading/(W·m-2) | 408.04 | |

Improving the insulation performances and air tightness of the buildings may be performed by means of the following measures:

1) To control the shape coefficient and the exposure window area of residential buildings.

2) To improve the thermal insulation capacity of external doors and windows, the roof and the floor.

3) To promote the wall internal and external thermal insulation technology.

4) Wide application of plastic or insulated aluminum alloy double-layer glass or hollow glass windows.

5) To lower the heat transfer coefficient of the roof construction.

For ensuring the effect of the heat consumption of the thermal insulation layer, some energy saving heat preservation measures, such as single-layer glass with wood frame windows, external wall and roof thermal insulation polystyrene boards in various thicknesses, were taken based on our building model to compare the room unit area heat consumption changes (Table 4). It is seen that the unit area heat consumption may be lowered by nearly 60% while the thickness of the thermal insulation layer is up to 8cm.

Table 4 Thermal insulation layer thickness vs the room unit area heat consumption

| Thermal insulation layer thickness /cm | Unit area heat consumption /(W·m-2) |

| 5 | 62.72 |

| 6 | 59.59 |

| 7 | 57.08 |

| 8 | 55.04 |

5 Rural “Coal-to-Gas” Demonstration Project

Beijing Gas Group has been performing the “coal-to-gas” pilot work in Xindian Village, Machikou Town, Changping District, and Caituo Village, Yukou Town, Pinggu District, in accordance with requirements of the urban pipe networks radiation to the rural regions of Division of Key Tasks of Beijing 2013-2017 Clean Air Action Plan (Beijing Government Office Document No.:[2013]49), issued by the People's Government of Beijing Municipality since 2013, and 700 households changed their heating and cooking modes in total.

Based on the work in 2013, Beijing Gas Group continued to expand the “coal-to gas” pilot work in 7 villages, such as Maquanying Village of Chaoyang District, Langying Village of Tongzhou District, and Caiyu Town of Daxing District in 2014, and 2,554 households realized the rural “coal-to-gas”work in total.

In accordance with the working measures in 2015 of Division of Key Tasks of Beijing 2013-2017 Clean Air Action Plan (Beijing Government Office Document No.: [2015] 7), issued by the People's Government of Beijing Municipality and the Related Policy Suggestions on Perfection of “Coal-to-Electricity” and “Coal-to-Gas” in Beijing Rural Regions (Beijing New Countryside Construction Office Document No.: [2015]1) jointly issued by the Comprehensive Office of Beijing Socialism New Countryside Construction Leading Group, Beijing Development and Reform Commission, Beijing Finance Bureau and Beijing Municipal Administration, the rural “coal-to-gas” work was completed in 2015 as for 1,846 households in 9 villages in total.

In view of the implementation effects, the effect of “coal-to-gas” is significant, and better environmental and social benefits were achieved.

6 Comparison and Division of Beijing Rural Gas Supply Methods

6.1 Comparison of gas supply methods

Under normal circumstances, the “coal-to-gas” primarily performed by means of the pipeline gas supply, CNG gas supply station and LPG methods, whose supply processes and characteristics are as follows:

6.1.1 Pipeline gas supply method

The pipeline gas supply method refers to connecting with the existing medium-pressure municipal natural gas pipeline, through the paved medium-pressure natural gas pipelines, low and medium pressure regulating boxes, the low-pressure pipeline, and the rural gas pipelines to the residential buildings, and suppling gas to households.

This method takes advantages of stable gas supply, cheap gas price, small land coverage and so on, but it is restricted by the rural surrounding natural gas pipe networks, roads and village conditions.

6.1.2 CNG gas supply station method

The CNG station method refers to supplying gas to households through the CNG supply stations in villages, medium and low pressure regulation, and the rural low pressure pipelines to the residential buildings.

The specific processes are as follows: gas is transferred from the close CNG bus stations through CNG long tube trailers, including tractors and gas storage devices, to the CNG supply stations as gas supply sources for consumption, and while the gas storage devices are used up, tractors draw them to the close CNG bus stations for filling. CNG supply stations include the primary pressure regulator which is 1.6MPa and the secondary pressure regulator which is low pressure, and low pressure natural gas from the stations is supplied to residential buildings for the use of households through the village gas pipelines.

This method takes advantages of flexible construction, easy transportation, and wide supply scope and so on. On the other hand, the construction investment is high and long tube trailers length is too long which is 15m, and transportation may be restricted by the roads conditions, and the filling gas capacity gas bus stations may be one influencing factor.

6.1.2 LPG method

The LPG method refers to a rural “coal-to-gas” solution by means of LPG cylinders.

The LPG method is applicable to the remote areas such as the mountain area and those remote areas where pipelines and CNG supply stations may not be constructed, but cooking gas may be applied. If the heating demands are satisfied, the costs are relatively high with the heating cost per household about RMB 7000 Yuan per year, which is far beyond the household heating economy capacity.

As for the two popular application methods, pipeline and CNG supply stations, various villages in Beijing shall take their application conditions and costs, and the actual applications is of great importance to guide implementation of the rural “coal-to-gas” projects. Our model was established to analyze the application scopes of the pipeline gas supply and CNG supply station methods.

6.2 Composition of rural “coal-to-gas” investment

The investment components of a rural “coal-to-gas” include 3 parts, the gas source part, the village part and the household part.

1) The gas source part: in view of the pipeline gas supply method, the investment is for the project of medium pressure pipeline and low and medium pressure regulating boxes connecting with the medium-pressure municipal natural gas pipeline. In view of the CNG supply station method, the investment is for the project of CNG supply stations.

2) The village part: the investment is for pipelines from the pressure regulating stations or CNG supplys tations to the household gas meters, and supporting devices, accessories and so on.

3) The household part: the investment is for pipelines from gas meters to the households, and stoves, gas wall hung boilers and so on.

6.3 Boundary conditions for measurement of a supplymethod

The investment components of a rural “coal-to-gas” indicate that investments of the gas source parts are primarily different for various gas supply methods. In view of the two gas supply methods, pipeline gas supply and CNG supply stations, comprehensive judgment may be carried out in accordance with the gas source investment, business costs and incomes and the model may be established based on the principle of balancing business costs and incomes, to put forward the basis for division of Beijing rural gas supply methods, and the basic data for the model analysis are as follows:

1) Gas volume prediction: based on comprehensive analysis of current gas consumption situations of those typical demonstration villages, and the actual investigation results of the rural gas consumption levels, The yearly residential gas consumption index in the model is 140m3 per household, and the person number per household refers to the 2.7 persons household size of Beijing 6th population cens, and the yearly heating gas consumption index is 9 m3/m2. By taking the phenomenon of farmers going out and working, and some farmers not using natural gas due to their ideas into account, the rural gas consumption ratio was taken as 85% for calculation.

2)The investment of the gas source for the pipeline gas supply method: in accordance with the current rural gas pipeline conditions, the construction investments of the medium-pressure pipeline projects outside villages and medium and low pressure regulating boxes are regarded as the investment of the gas source for the pipeline gas supply method. By considering the directly influence of pipeline length, the investments for 0.5km, 1.0km and 1.5km natural gas pipelines were calculated by means of our model.

3) The investment of the gas source for the CNG supply station method: in view of the small difference between the investment of different size villages, the construction investment of a CNG supply station per village was taken as RMB 2,400,000 Yuan for simplifying the model.

4) Sales prices: pipeline gas prices are RMB 2.28 Yuan/m3, and CNG supplys tation prices are RMB 2.91 Yuan/m3.

5) Purchasing price: pipeline gas is RMB 1.86 Yuan/m3, and CNG supply station is RMB 2.23 Yuan/m3.

6) Personnel allocation: patrol inspection is 1 person per village, and a CNG supply station is 2 persons, and the yearly payment is RMB 60,000 Yuan per person.

7) Purchasing fuel and power including taxes: electricity price is RMB 0.9319 Yuan/kW×h, and water price is RMB 8.15 Yuan/ton.

8) Depreciation: the comprehensive fixed assets depreciation period is19 years, based on the calculation of straight-line depreciation method, the residual value rate is 4%.

9) Repair fee is 1.5% of the investment of the medium-pressure natural gas pipelines and medium and low pressure regulating boxes or the CNG supply station.

10) Other expenses: the management fee is 30% of personnel wages and additional charges, operating expenses are 1.0% of the sales revenue, manufacturing costs are 10% of the repair fee, and the safety productioncosts are 1.5% of the sales revenue.

6.4 Selection of a supply method

6.4.1 Economic measurement results of various gas supply methods

In accordance with the calculation boundary conditions listed in Section 6.3, the economic measurement results of the rural pipeline gas supply method and the CNG supply station method are shown in Table 5 and 6.

Table 5 The economic measurement results of the rural pipeline gas supply method

Beijing Gas Group has been performing the “coal-to-gas” pilot work in Xindian Village, Machikou Town, Changping District, and Caituo Village, Yukou Town, Pinggu District, in accordance with requirements of the urban pipe networks radiation to the rural regions of Division of Key Tasks of Beijing 2013-2017 Clean Air Action Plan (Beijing Government Office Document No.:[2013]49), issued by the People's Government of Beijing Municipality since 2013, and 700 households changed their heating and cooking modes in total.

Based on the work in 2013, Beijing Gas Group continued to expand the “coal-to gas” pilot work in 7 villages, such as Maquanying Village of Chaoyang District, Langying Village of Tongzhou District, and Caiyu Town of Daxing District in 2014, and 2,554 households realized the rural “coal-to-gas”work in total.

In accordance with the working measures in 2015 of Division of Key Tasks of Beijing 2013-2017 Clean Air Action Plan (Beijing Government Office Document No.: [2015] 7), issued by the People's Government of Beijing Municipality and the Related Policy Suggestions on Perfection of “Coal-to-Electricity” and “Coal-to-Gas” in Beijing Rural Regions (Beijing New Countryside Construction Office Document No.: [2015]1) jointly issued by the Comprehensive Office of Beijing Socialism New Countryside Construction Leading Group, Beijing Development and Reform Commission, Beijing Finance Bureau and Beijing Municipal Administration, the rural “coal-to-gas” work was completed in 2015 as for 1,846 households in 9 villages in total.

In view of the implementation effects, the effect of “coal-to-gas” is significant, and better environmental and social benefits were achieved.

6 Comparison and Division of Beijing Rural Gas Supply Methods

6.1 Comparison of gas supply methods

Under normal circumstances, the “coal-to-gas” primarily performed by means of the pipeline gas supply, CNG gas supply station and LPG methods, whose supply processes and characteristics are as follows:

6.1.1 Pipeline gas supply method

The pipeline gas supply method refers to connecting with the existing medium-pressure municipal natural gas pipeline, through the paved medium-pressure natural gas pipelines, low and medium pressure regulating boxes, the low-pressure pipeline, and the rural gas pipelines to the residential buildings, and suppling gas to households.

This method takes advantages of stable gas supply, cheap gas price, small land coverage and so on, but it is restricted by the rural surrounding natural gas pipe networks, roads and village conditions.

6.1.2 CNG gas supply station method

The CNG station method refers to supplying gas to households through the CNG supply stations in villages, medium and low pressure regulation, and the rural low pressure pipelines to the residential buildings.

The specific processes are as follows: gas is transferred from the close CNG bus stations through CNG long tube trailers, including tractors and gas storage devices, to the CNG supply stations as gas supply sources for consumption, and while the gas storage devices are used up, tractors draw them to the close CNG bus stations for filling. CNG supply stations include the primary pressure regulator which is 1.6MPa and the secondary pressure regulator which is low pressure, and low pressure natural gas from the stations is supplied to residential buildings for the use of households through the village gas pipelines.

This method takes advantages of flexible construction, easy transportation, and wide supply scope and so on. On the other hand, the construction investment is high and long tube trailers length is too long which is 15m, and transportation may be restricted by the roads conditions, and the filling gas capacity gas bus stations may be one influencing factor.

6.1.2 LPG method

The LPG method refers to a rural “coal-to-gas” solution by means of LPG cylinders.

The LPG method is applicable to the remote areas such as the mountain area and those remote areas where pipelines and CNG supply stations may not be constructed, but cooking gas may be applied. If the heating demands are satisfied, the costs are relatively high with the heating cost per household about RMB 7000 Yuan per year, which is far beyond the household heating economy capacity.

As for the two popular application methods, pipeline and CNG supply stations, various villages in Beijing shall take their application conditions and costs, and the actual applications is of great importance to guide implementation of the rural “coal-to-gas” projects. Our model was established to analyze the application scopes of the pipeline gas supply and CNG supply station methods.

6.2 Composition of rural “coal-to-gas” investment

The investment components of a rural “coal-to-gas” include 3 parts, the gas source part, the village part and the household part.

1) The gas source part: in view of the pipeline gas supply method, the investment is for the project of medium pressure pipeline and low and medium pressure regulating boxes connecting with the medium-pressure municipal natural gas pipeline. In view of the CNG supply station method, the investment is for the project of CNG supply stations.

2) The village part: the investment is for pipelines from the pressure regulating stations or CNG supplys tations to the household gas meters, and supporting devices, accessories and so on.

3) The household part: the investment is for pipelines from gas meters to the households, and stoves, gas wall hung boilers and so on.

6.3 Boundary conditions for measurement of a supplymethod

The investment components of a rural “coal-to-gas” indicate that investments of the gas source parts are primarily different for various gas supply methods. In view of the two gas supply methods, pipeline gas supply and CNG supply stations, comprehensive judgment may be carried out in accordance with the gas source investment, business costs and incomes and the model may be established based on the principle of balancing business costs and incomes, to put forward the basis for division of Beijing rural gas supply methods, and the basic data for the model analysis are as follows:

1) Gas volume prediction: based on comprehensive analysis of current gas consumption situations of those typical demonstration villages, and the actual investigation results of the rural gas consumption levels, The yearly residential gas consumption index in the model is 140m3 per household, and the person number per household refers to the 2.7 persons household size of Beijing 6th population cens, and the yearly heating gas consumption index is 9 m3/m2. By taking the phenomenon of farmers going out and working, and some farmers not using natural gas due to their ideas into account, the rural gas consumption ratio was taken as 85% for calculation.

2)The investment of the gas source for the pipeline gas supply method: in accordance with the current rural gas pipeline conditions, the construction investments of the medium-pressure pipeline projects outside villages and medium and low pressure regulating boxes are regarded as the investment of the gas source for the pipeline gas supply method. By considering the directly influence of pipeline length, the investments for 0.5km, 1.0km and 1.5km natural gas pipelines were calculated by means of our model.

3) The investment of the gas source for the CNG supply station method: in view of the small difference between the investment of different size villages, the construction investment of a CNG supply station per village was taken as RMB 2,400,000 Yuan for simplifying the model.

4) Sales prices: pipeline gas prices are RMB 2.28 Yuan/m3, and CNG supplys tation prices are RMB 2.91 Yuan/m3.

5) Purchasing price: pipeline gas is RMB 1.86 Yuan/m3, and CNG supply station is RMB 2.23 Yuan/m3.

6) Personnel allocation: patrol inspection is 1 person per village, and a CNG supply station is 2 persons, and the yearly payment is RMB 60,000 Yuan per person.

7) Purchasing fuel and power including taxes: electricity price is RMB 0.9319 Yuan/kW×h, and water price is RMB 8.15 Yuan/ton.

8) Depreciation: the comprehensive fixed assets depreciation period is19 years, based on the calculation of straight-line depreciation method, the residual value rate is 4%.

9) Repair fee is 1.5% of the investment of the medium-pressure natural gas pipelines and medium and low pressure regulating boxes or the CNG supply station.

10) Other expenses: the management fee is 30% of personnel wages and additional charges, operating expenses are 1.0% of the sales revenue, manufacturing costs are 10% of the repair fee, and the safety productioncosts are 1.5% of the sales revenue.

6.4 Selection of a supply method

6.4.1 Economic measurement results of various gas supply methods

In accordance with the calculation boundary conditions listed in Section 6.3, the economic measurement results of the rural pipeline gas supply method and the CNG supply station method are shown in Table 5 and 6.

Table 5 The economic measurement results of the rural pipeline gas supply method

| Single village size /households | Yearly gas consumption/(m3·a-1) | Peak hourly gas consumption /(m3·h-1) | Yearly income /(Yuan·a-1) | Yearly business costs /(Yuan·a-1) | ||

| L=0.5km | L=1.0km | L=1.5km | ||||

| 350 | 36.6×104 | 210.3 | 83.4×104 | 82.5 ×104 | 91.4×104 | 100.2×104 |

| 400 | 41.8×104 | 240.3 | 95.3×104 | 92.3×104 | 101.1×104 | 109.9×104 |

| 500 | 52.2×104 | 300.4 | 119.1×104 | 111.7×104 | 120.5×104 | 129.4×104 |

| 600 | 62.7×104 | 360.5 | 142.9×104 | 145.1×104 | 144.2×104 | 153.1×104 |

| 650 | 67.9×104 | 390.5 | 154.8×104 | 135.4×104 | 153.9×104 | 162.8×104 |

| 700 | 73.1×104 | 420.6 | 166.7×104 | 157.4×104 | 168.6×104 | 179.8×104 |

| 800 | 83.6×104 | 480.7 | 190.5×104 | 176.9×104 | 188.0×104 | 199.2×104 |

| 900 | 94.0×104 | 540.7 | 214.4×104 | 196.3×104 | 207.5×104 | 218.6×104 |

| 1000 | 104.5×104 | 600.8 | 238.2×104 | 216.7×104 | 227.9×104 | 239.1×104 |

| 1100 | 114.9×104 | 660.9 | 262.0×104 | 236.4×104 | 243.0×104 | 251.9×104 |

Table 6 The economic measurement results of the rural CNG supply station method

| Single villagesize / households | Yearly gas consumption/(m3·a-1) | Peak hourly gas consumption /(m3·h-1) | Yearly income /(Yuan·a-1) | Yearly business costs /(Yuan·a-1) |

| 250 | 26.1×104 | 150.2 | 76.0 ×104 | 85.2×104 |

| 300 | 31.4×104 | 180.3 | 91.2×104 | 96.9×104 |

| 350 | 36.6×104 | 210.3 | 106.4×104 | 108.5×104 |

| 400 | 41.8×104 | 240.3 | 121.6×104 | 120.2×104 |

| 450 | 47.0×104 | 270.4 | 136.8×104 | 131.8×104 |

| 500 | 52.2×104 | 300.4 | 152.0×104 | 143.8×104 |

| 550 | 57.5×104 | 330.5 | 167.2×104 | 156.3×104 |

| 600 | 62.7×104 | 360.5 | 182.4×104 | 167.9×104 |

| 650 | 67.9×104 | 390.5 | 197.6×104 | 179.6×104 |

| 700 | 73.1×104 | 420.6 | 212.8×104 | 191.2×104 |

| 750 | 78.3×104 | 450.6 | 227.8×104 | 202.9×104 |

6.4.2 The applicable range of the pipeline gas supply method

1) the source conditions: the pipeline gas supply method is applicable to those villages which is <0.5km from the municipal natural gas pipelines and above 350 households, <1km from the municipal natural gas pipelines and above 650 households, or 1.5km from the municipal natural gas pipelines and above 1,100 households.

2) The village roads are two-lane roads and ready for connecting the pipeline network.

3) The village primary roads are basically two-lane road, and branch roads are basically >3m in width, and ready for pavement of low pressure natural gas pipelines in villages.

4) The village is ready for construction of pressure regulating boxes, and suppling gas after regulating the pressure to rural users.

6.4.3 The applicable range of the CNG supply station method

1) CNG supply projects shall be selected on premise of the government subsidizing the natural gas price to farmers.

2) The CNG supply method is applicable for above 400 households.

3) Villages shall be in plain areas and the roads shall be good to satisfy operation requirements for CNG long tube trailers.

7 Promotion of the LNG Cylinder Group Method

In the rural “coal-to-gas” practice, the impact factors include the construction period, land coverage, project investment and operation costs, especially the transportation conditions and so on. Promotion of CNG supply stations may be restricted to a certain extent.The new LNG small cylinder group gasification stations may be better utilized for gas supply to solve the above issues.

The LNG small cylinder group gasification station method refers to transferring LNG stored in LNG cylinders from LNG storage and distribution stations to LNG small cylinder group gasification stations by means of the LNG tankers, and going out of the low-pressure natural gas pipelines to to flow through the village pipelines to the household for consumption after vaporizing, pressure regulating, metering and odorization.

The LNG small cylinder group method takes advantages of flexible construction, easy transportation, wide gas supplyvrange, saving electricity, low transportation costs, rapid applications in small towns, areas where there are no rural gas supply temporarily or permanently, gas consumption is generally <2000Nm3/d, and gas storage volume for consumption can supply for 1-3 days.

The standardization design parameters for a LNG small cylinder group gasification station is shown in Table 7, and it will reduce the management complexity and manufacturing costs, and improve the equipment quality. Moreover, it may be quickly put into application in a small town, and it may also utilized in those areas where there will no gas pipeline temporarily or permanently. Thus, the LNG small cylinder group gasification station method shall be ideal for natural gas supply in the non-pipeline transportation technologies.

Table 7 The standardization design parameters for a LNG small cylinder group gasification station

| Design flow rate /(m3·h-1) | 100~500 |

| Pipeline design pressure before a pressure regulator /Mpa | 1.6 |

| Pipeline design pressure after a pressure regulator /Mpa | 0.4 |

| Design temperature at the air vaporizer inlet /°C | -196 |

| Design temperature at the air vaporizer outlet /°C | -10 |

| Ambient temperature /°C | -20~50 |

| Operating pressure at the pressure regulator outlet /mpa | 0.1 |

| Operating temperature at the pressure regulator outlet/°C | ≥0 |

8 Existing Issues for Beijing Rural Gas Supply

Although the rural “coal-to-gas” projects are of vital significance for improving the atmospheric environment and the farmers' living standard, there are many issues to be solved. By integrating the current situations of Beijing demonstration projects, the main issues for Beijing rural gas supply were summarized as follows:

8.1 Project approval

Promotion of any rural “coal-to-gas” project shall be necessarily supported in policies, such as handling project approval, planning, and bidding and construction procedures.

8.2 Design

There are various types of houses, and the interior design is difficult, moreover, safety spacing is not enough for some villages so that the ground pavement requirements may not be satisfied, thus, the external climbing method may be taken necessarily.

8.3 Construction

Some villagers do not cooperate, understand or refuse construction or dismantling, in addition, the rural houses are in various types, and the projects of low pressure primary and secondary pipelines and the inner-household pipelines are huge.

8.4 Training

The villagers may be trained for several times, and the training is difficult.

8.5 Operation

Rural residents' safety consciousness is poor, and they sometimes hangs hang off fire crackers in the pipelines, or saw, disassemble pipelines, or destruct pressure regulating facilities or thermal insulation lamp gas devices.

9. Conclusions and Suggestions

9.1 Conclusions

1) The total application amount of rural scattered coal accounts for a relatively small proportion in the urban primary energy, but its effect of haze generation shall not be negligible.

2) If natural gas is utilized to replace scattered coal, the thermal insulation shall be carried out to houses, and while the thermal insulation layer thickness is up to 8cm, the unit area heat consumption falls by nearly 60%, and the effect is significant.

3) The LPG method is applicable to the remote areas, such as the mountain area and those remote areas where pipelines and CNG supply stations may not be constructed, but cooking gas may be applied. If the heating demands are satisfied, the costs are relatively high, heating cost per household is about RMB 7,000 Yuan per year, which is far beyond the household heating economy capacity.

4) While the pipeline gas supply conditions are ready, the economic distances for 350 households per villages, 600 households per village and 1000 households per villages are 0.5km, 1.0km and 1.5km, respectively.

On the other hand, while the pipeline gas supply conditions are not ready, the CNG supply method may be used, which is specially recommended for gas supply for 400 households per village.

5) In the rural “coal-to-gas” practice, the impact factors include the construction period, land coverage, project investment and operation costs, especially the transportation conditions and so on. Promotion of CNG supply stations may be restricted to a certain extent, and the new LNG small cylinder group gasification stations shall be promoted in the rural “coal-to-gas” projects.

9.2 Suggestions

1) The gas enterprise project income index standards shall be formulated in the unified way based on full measurement to first guarantee the enthusiasm of gas companies, and reduce the pressure of government subsidies.

2) The subsidy policy shall be perfected. Because of the huge investment and low gas consumption in villages, and the gas companies being difficultly maintaining the operation, repairing and depreciation costs within the pipeline life cycle, it is suggested that the urban government shall formulate the operation subsidy policy.

3) It is suggested that the advantages of the LNG small cylinder group supply method shall be fully utilized to solve the “coal-to-gas” demands of medium or small sized villages pipelinegas may not be supplied to.

4) More economical and efficient application methods shall be explored, such as coupling of the gas heat pumps and air source heat pumps, and how to improve the rural energy utilization efficiency and economy shall be closely studied and integrated.

京公网安备 11010502042381号

京公网安备 11010502042381号